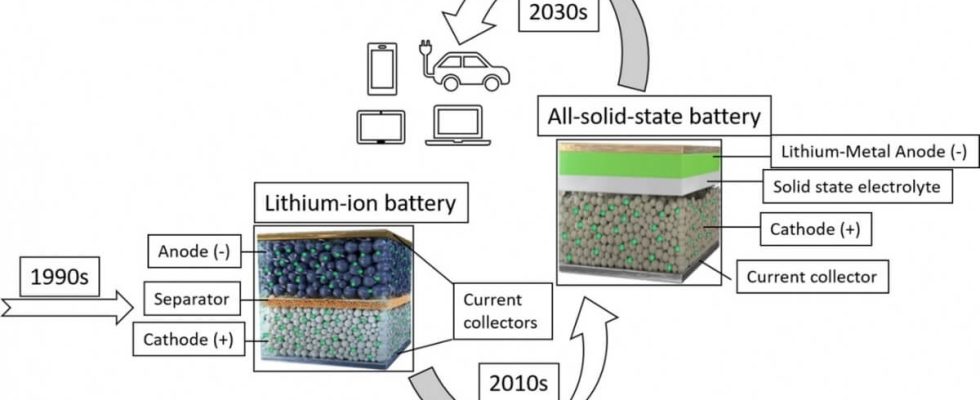

Toyota Motor and Idemitsu Kosan have formed a strategic partnership to advance mass production of all-solid-state batteries. As electric vehicles (EVs) continue to gain importance, battery technology is at the center of development efforts. Solid-state batteries are positioned as a major innovation in the field of electric vehicles, promising advantages in terms of range, charging speed and ultimately cost compared to traditional liquid electrolyte batteries. But will these two industry giants be able to fulfill their promises?

The world’s largest automobile manufacturer by sales volume Toyotaannounced earlier this year that it had made a “technological breakthrough” in solid-state batteries, signaling that it is committed to researching and addressing long-standing durability issues with this technology.

Idemitsu Kosan, Japan’s second-largest oil refiner, is no newcomer to the electric vehicle world, having invested in Delta Lithium, an Australian lithium developer. The company is actively engaged in electric vehicle battery supply chains, in line with Toyota’s vision for the future of mobility.

According to their recent joint statement, the partnership aims to commercialize next-generation solid-state batteries by 2027-28 and then quickly move into full-scale mass production. If their plans come true, electric vehicle enthusiasts can expect vehicles equipped with solid-state batteries to offer an impressive range of 1,200 kilometers and a remarkable charging time of just 10 minutes. Considering the current state of technology, these claims almost sound too good to be true. In particular, the significant cost associated with these advanced batteries remains a significant barrier. While the benefits are obvious, the price tag poses a significant challenge.

The focus of the collaboration revolves around sulfide solid electrolytes, known for their potential to provide high capacity and output for electric vehicles. These electrolytes are characterized by their softness and stickiness, making them suitable for mass production of batteries. The first phase of the collaboration will focus on the development of these sulfide solid electrolytes and will result in the establishment of a large-scale pilot plant. In the next stages, mass production will begin in this facility and Toyota plans to integrate these batteries into its electric vehicles. The final phase requires comprehensive exploration of full-scale mass production and commercialization, paving the way for significant advances in electric vehicle battery technology.