On Tuesday, September 3, the Flamanville EPR came to life. A nuclear chain reaction was started in the core of this new reactor, expected 12 years late by the entire industry. Gradually, the installation will have to ramp up before being connected to the electricity grid “by the end of autumn”, as EDF indicates. But for the French energy company, the moment is historic. On two counts. Not only is Flamanville the first reactor inaugurated in 25 years, but its start-up marks the beginning of the biggest challenge for the French energy company since the Messmer plan in the 1970s. Indeed, EDF plans, over the next twenty years, to build six new EPR2s on the sites of three existing power plants, and eight more as an option. The success of this ambitious plan will largely depend on learning from past mistakes and regaining our expertise in nuclear power, underlines Claude Jaouen, former director of Areva’s reactor activity, restructured in 2018.

L’Express: Flamanville has become the symbol of extremely costly and complex nuclear power. What lessons have you learned from this “cursed” project?

Claude Jaouen: The first lesson is that with 25 years without a major project in France, there is a certain amount of know-how that needs to be regained. I am talking about technical, engineering and organisational skills. Feedback from the Olkiluoto construction site in Finland and the Flamanville construction site also showed that the entire supply chain needed to be strengthened. In both cases, we realised late in the day that we no longer had the capacity and the necessary history for such complex construction sites. The latter require extremely high standards. And this translates concretely into a mass of documentation, justifications and corrections that are the cause of many delays. These elements must be taken into account from the start. This is the main way to improve the EPR 2 and its future programme.

Finally, Flamanville teaches us that it is essential to have a stable regulatory framework throughout the project. This was not the case. For example, the regulations on pressure vessels – they regulate all the piping – evolved during the project. Some components had been ordered as early as 2006, but new regulations concerning these products arrived in 2010 and the Nuclear Safety Authority (ASN) wanted to make them applicable retroactively. This cost us dearly in rework and additional delays. On a steam generator – one of the main parts of the reactor core – we had up to 1,500 interruptions during the manufacturing process. Imagine the documentation and reorganization required. It is extremely penalizing. If we start with a clear regulatory framework, the construction process is easier and manufacturing smoother.

The next EPR is to be built on the Penly power plant site (Seine-Maritime) by 2040. How will it be different from Flamanville?

Its overall architecture is simplified, with lower reinforcement rates – the proportion of steel in the concrete – and better alignment of the walls. However, the EPR2 remains quite similar to the Flamanville reactor. Most of the components will therefore be used again. It will be the same turbine, the same power… Feedback will therefore count for a lot. Especially since the Folz report, published in 2019, already pointed out precisely which elements are the cause of the delays and additional costs. All this thinking has been integrated into the way the EPR2 is designed.

There is much talk of the series effect, which should enable EDF to gain efficiency in the construction of future reactors. But what about the organization of the company? Will it be up to the industrial challenge?

You are right. This point is essential to accelerate the construction of the next EPRs. Today, the relaunch of a nuclear program over twenty years, and possibly more, provides visibility for investment, recruitment, etc. A lot of work has been done around supply chains. This translates into a strengthening of partnerships with subcontractors. This is why the costs and deadlines observed on the Flamanville construction site cannot be used as a reference for the future. Luc Rémont, CEO of EDF, has set a deadline of around six years for the construction of the next reactors. This may seem ambitious. But when we look at what other countries are doing, we see that this is more or less the norm. In all likelihood, the organization of the project, the development of know-how, and the visibility given to the entire value chain should guarantee the smooth running of the program. Historically, the series effect has always ended up playing a role. The first reactor built in France cost much more than expected and its construction took 10 years, while the latest reactors required 5 years of construction and were 40% less expensive to manufacture.

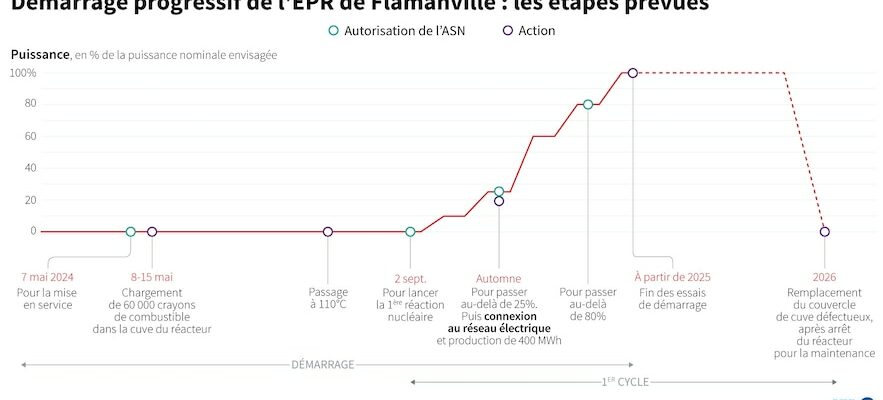

Gradual start-up of the Flamanville EPR: the planned stages

© / afp.com/Nalini LEPETIT-CHELLA, Laurence SAUBADU

EDF’s ambition is also to increase its contracts abroad to ensure its economic sustainability and the maintenance of know-how… Does that seem credible to you?

Construction sites abroad can indeed help accelerate in France, but only to a certain extent. Of course, these contracts maintain know-how, but they confront the company with other regulatory contexts. Building in other countries also involves a new supply chain, which leads to difficulties. We see this with the Hinkley Point construction site in England. The first construction sites in a series are proving complicated. But I am not convinced that this plays a major role in our ability to meet the construction targets for future reactors on French soil.

Faced with American, Korean or even Chinese competitors, can we still gain market share?

In the list of our competitors, let’s not forget the Russians. They are the first on the export market, with a particular pattern since they provide the financing. But in Europe, we do indeed see quite strong competition from the Americans with Westinghouse and the Koreans with KHNP. We know that the countries of the European Union are quite reluctant to turn to Russia and China for geopolitical reasons that are easily understood. However, within the European community, continental preference does not play much, which leaves a good place for American and Korean competitors. And the examples of Flamanville and Olkiluoto in Finland, on which EDF has accumulated heavy delays, create a history that is unfavorable to France.

When you’re called EDF and you’re fifteen years behind in building a reactor in your own country, that doesn’t really appeal to potential customers. However, many programs have been launched in Europe and there’s still room for improvement. It’s not just the Czech Republic and Poland that are opening new power plants. We’re established in England, where other projects could see the light of day because there’s a political will to pursue a nuclear program there. It’s up to us to seize this opportunity.

The cost of the EPR will still be decisive, while we know that the bill for the Flamanville EPR is now estimated at 13.2 billion euros by EDF, i.e. four times the initial estimate…

Financial overruns go hand in hand with longer deadlines. When the Flamanville construction site was launched, the construction cost was around one million euros per day! Obviously, at this rate, the bill quickly becomes abysmal. However, I remain convinced that the cost of the Flamanville EPR, or the one built in Finland, is much higher than that of a mass-produced EPR!

.