The aircraft manufacturer is clearly blamed. Several bolts supposed to block the door of a Boeing 737 MAX 9 which came loose in early January during an Alaska Airlines flight were missing, according to the American Transportation Safety Agency (NTSB).

According to the NTSB’s preliminary report, the lack of wear or deformation around some of the holes “indicates that four bolts intended to prevent the cap holder from moving upward were missing before it moved.”

Employees removed the bolts

The agency has collected written documents and photos that show Boeing employees removed four bolts at these locations during an inspection at the Renton plant in Washington state, in the northwest of the United States. ) before delivery of the plane last October. The operation was carried out to replace five damaged rivets in the cabin of the aircraft. Other photos taken after the rivets were changed show that in at least three points, bolts had not been reinstalled.

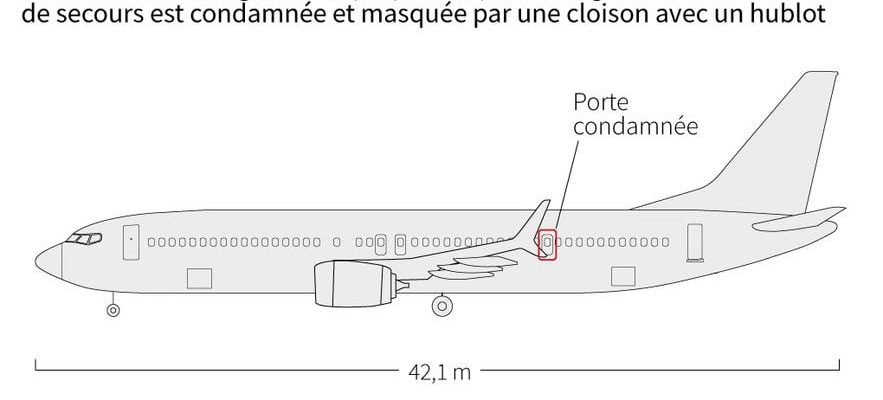

This door was used to block an exit and was not intended to be opened, this model already having enough emergency exits in this configuration.

On January 5, it came unstuck during the ascent of the Alaska Airlines MAX 9 which was to connect Porland (Oregon) to Ontario (California). The incident left only a few minor injuries.

Before the NTSB report was released, Alaska Airlines had already reported “poorly secured equipment” after preliminary inspections. Owner of the largest fleet of Boeing 737 MAX 9s (79 aircraft), United Airlines said it had discovered, during checks, “bolts that needed to be tightened”.

The Boeing 737 MAX 9

© / afp.com/Jonathan WALTER, Jean-Michel CORNU

“Accountable”

In recent months, the American aircraft manufacturer Boeing has experienced other episodes of failure and has notably had to slow down its deliveries due to problems on the fuselage, in particular on the rear bulkhead of the aircraft. “Whatever the final conclusions” of the NTSB, “Boeing must be held accountable for what happened,” responded the general director of the aircraft manufacturer, Dave Calhoun, quoted in a press release.

“An event like this should not occur on an aircraft that leaves our factory,” insisted the manager, recalling that Boeing had already initiated a “comprehensive plan to strengthen the quality and confidence of (its) shareholders.”

After the incident on the Alaska Airlines flight, the American Civil Aviation Regulatory Agency (FAA) suspended 171 of the 218 737 MAX 9s already delivered. On Monday, it announced that 94% of the 144 aircraft of this model operated by United and Alaska had been inspected and authorized to resume flights.

Strengthen supervision of Boeing

Tuesday, during a Congressional hearing, the new head of the FAA, Mike Whitaker, considered it necessary to strengthen supervision of Boeing after the 737 MAX 9 incident.

“There have been problems (with Boeing) in the past and it appears that they have not been resolved,” the new FAA administrator, who took office in October, said during a hearing before the House Subcommittee on Aviation. “So we feel like we need to raise the level of supervision to deal with this,” he continued.

Mike Whitaker indicated that the FAA had dispatched around twenty inspectors to Boeing, currently at work to check the assembly conditions of the group’s aircraft. This approach, he specified, breaks with the methods traditionally used by the agency, which were essentially based on the study of documents transmitted by Boeing.

The FAA has commissioned a six-week audit from a specialized firm, which is currently being carried out, the conclusions of which will be used to define a new sustainable supervision method. “We haven’t made a decision yet, but I expect we will keep people on site,” the FAA boss said. Mike Whitaker also said that the regulator was considering no longer leaving Boeing, as is the case today, responsible for part of the quality control of its own planes, even if it meant going through a third-party service provider.