Today, eco-responsibility, innovation with Maxime Roux, Camille Callennec, Tanguy Blévin and Théo Joy, the four founders of Ostrea Design. Worktop, furniture tops, covering, Ostrea Design manufactures in France, a material made up of 65% recycled shell shells without any addition of petrosourced elements. The recycled shell marine material produced by Ostrea Design is similar to marble or natural stone.

I see creation in two points. There is business creation, but beyond that, the artistic dimension of Ostrea is something that we really like and that the team really likes. It’s a very strong choice for us to develop beautiful colors with natural pigments, to find shells that are pretty and to highlight them as much as possible.

Maxime Roux, one of the four co-founders ofOstrea Design.

“ We were looking for names linked to shellfish and therefore Ostrea: it is the root of oyster, the grammatical basis of oyster farming. We did several name tests and we settled on this name. »

Born in the Paris region, Maxime Roux attended engineering school in electronics and IT. He worked for five years in the technology sector for large companies, quite far from the world of design or decoration. He meets another co-founder at his workplace: Camille Callennec. With Tanguy Blévin and Théo Joy, the four founders of Ostrea Design, in Brittany, are committed to finding a solution to the problem surrounding the recycling of seashell shells and their revaluation.

“ This is the central subject of the project. When we see our backgrounds, apart from Théo who comes a little bit from that world, this is what was the common thread of the project and our investment even before arriving at the first prototype. The idea was to say that we were going to have an impact project. We didn’t know if it would be in the area of decoration, or if we were going to make road surfacing or something else with these shells. The idea, really, was first of all to provide a solution to a problem which was to use fewer resources by taking advantage of this waste which is ultimately resources. »

“ The shell is calcium carbonate, it is a limestone biomineral, so, rather than looking for stones in quarries, we have 250 000 tonnes of seashell shells produced each year in France which are accessible. The second objective in this project for the production of this material was to have a manufacturing process which will not use any petrosourced resin, and therefore which will have the lowest possible impact on the ecology. The goal: to have an aesthetic product with which we make worktops, furniture tops, that really happened secondarily, after having tested lots of things. Eco sensitivity is really the central point of both the team and the project. »

Ostrea Design has three sectors of application : furniture, worktop and floor covering through research and development with the stabilization of patented formulations.

“ We have formulations for each shell, for each shell particle size. We have many different formulations. We worked on these formulations with partner research laboratories, researchers too, who work part-time at Ostrea and who continue to do so more and more, since we have a major R&D program (research and development) over the next two years. »

“ There is all the know-how of Théo, firstly, who has a real knowledge of materials, who made the basis and then very specialized researchers on materials and biomaterials who brought us their expertise and who allowed us to evolve the basic work that we had done, which was work, I would say semi-professional, to arrive at something very professional. »

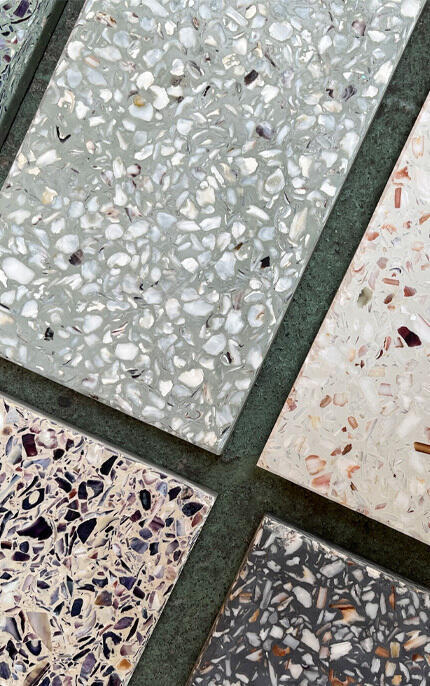

Coffee table, furniture top, worktop, the basic version of the Ostrea material is white, it is very lightly pigmented by the shell of the seashell. Mussels, oysters or scallops provide a fairly slight difference in color.

“ Each shell will have a very different universe in terms of visual rendering. The Ostrea aesthetic references are based on the shell. We carried out recycling tests on abalone clams and periwinkles, which are new worlds that are opening up in terms of rendering. The first constraint is the use of natural pigments, so we will be limited by what nature can give us in terms of color and especially durability over time, because certain natural pigments can change in the sun. Afterwards, when it comes to mixing a shell with a pigment, we have few limits. It is more, I would say, the codes of design and interior architecture which will define the associations that we will work on as a priority. »

“ Théo is the driving force for testing many things in this creative part, whether through the sizes of the glitter, the shells that will be chosen to develop new references and the pigments. We use green pigments, blue pigments, black pigments and pigments that I call terracotta. With these four pigments, the four colors in reference: a terracotta, which is a bit of a brick color, a black reference, we have two references of green, a green which is more of an intense green, a forest green, Irish green and a paler green which will be a sort of water green, gray green. And these are the four colors that we have standardized. »

Find all the episodes of 100% Création on:

Apple Podcast |Castbox |Deezer |Google Podcast |Addict Podcast |Spotifyor any other platform via the RSS feed.