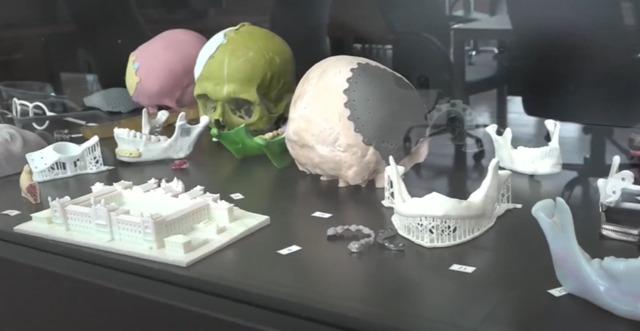

Skull, chest, jaw, spine… According to the news on Ekol TV Main News, spare parts for humans are produced at the Health Sciences University Gülhane Medical Design Center. Those who have suffered partial bone loss due to reasons such as terrorism, disasters, traffic accidents and gunshot wounds, or those who have had a portion of their bone tissue removed after surgical interventions for cancer or other diseases apply to this center with the guidance of their doctors.

MODELLING WITH 3D PRINTERS

The implants here are first modeled with 3D printers. Immediately after, after receiving approval from the physician, they are produced from titanium again with 3D printers and transplanted to the patient in this way.

IT IS DONE FOR BIG LOSSES

Gülhane METÜM Director Prof. Dr. Simel Ayyıldız said, “The treatments we are talking about are not routinely performed, cannot be performed, in other words, they are big losses. Or, we design and produce the parts that affect the vital situation and cannot be completed from other parts of the body in three dimensions based on the data coming from the patient’s tomography.

“The patient’s physicians in relevant clinics such as brain and neurosurgery, orthopedics, plastic surgery, and thoracic surgery should first recommend this treatment. We work on how and with what kind of part we will complete the missing part of the design for each patient and complete it in the virtual environment first,” he said.

SBÜ Rector Prof. Dr. Kemalettin Aydın stated, “We are a center that manufactures personalized products. We are a center whose fees can be paid by the Social Security Institution in Turkey. Nearly a thousand patients whose lives have become extremely high quality, comfortable and livable have been formed in a period of 13 years to date.”