Taiwanese founder TSMC will produce next-generation chips from 2022 for increased performance and reduced consumption. Among the first customers, Apple, for its Macs and iPhones, but also Intel …

The race for fine engraving of electronic circuits is not about to end, on the contrary! Thus, according to DigiTimes Asia, TSMC has just launched preproduction tests of chips engraved in 3 nm. According to experts, the Taiwanese founder could even go into mass production in the fourth quarter of 2022 and thus deliver its privileged customers with new generation processors in the process. Certainly, this is not really the kind of news that raises enthusiasm crowds. Yet it is thanks to this kind of technological advancement that our beloved high-tech devices – in particular our smartphones and our computers – are both more efficient and more energy efficient. And information takes on its full importance when you know who TSMC is and who its main customers are …

Apple chips in 3 nm for 2022

TSMC stands for Taiwan Semiconductor Manufacturing Company, one of the largest integrated circuit manufacturers in the world. It is even the biggest independent “founder” on the planet. Above all, it is the one that has been implementing for years the most sophisticated technologies to produce electronic chips: main processors (CPU), graphics processors (GPU), but also SoCs (for system-on-a-chip, or systems integrated on a circuit), such as those found in smartphones, tablets and many other mobile devices. Very much sought after, especially during this shortage period (see our article), TMSC counts among its customers several giants in the sector who do not manufacture their own chips: AMD, whose processors are used in many PCs but also in PlayStation and game consoles. Xbox, Nvidia, the specialist in graphics circuits which gamers love, Qualcomm, the specialist in SoCs for smartphones, and, above all… Apple!

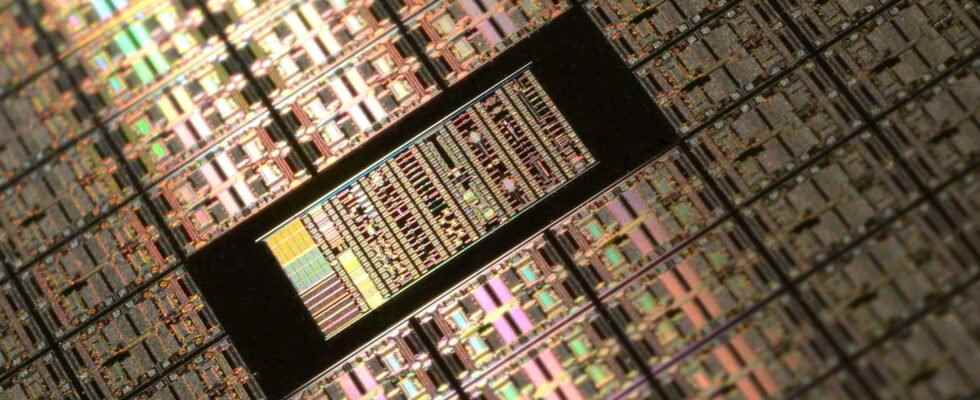

It is also thanks to TSMC that the firm at the apple can produce Soc as sophisticated and efficient as its famous A15 Bionic which powers the iPhone 13 or the M1 that we find on the new Macs, and which ridicule some Intel processors. Because if it is indeed the Apple engineers who design these high-end chips, it is the TMSC production lines which manufacture them from wafers, these semiconductor wafers in which the circuits are cut. And each technical progress made by the founder benefits Apple, which is at the forefront of its customers.

More efficient and economical processors

So, while Intel and others in the industry have long been stuck with 12nm engraving, TSMC was the first to reach 7nm, which is used today for most Ryzen processors, which made it possible it is up to AMD to take a prominent place in the PC CPU market. Since then, the founder has made further progress by setting up production lines capable of working in 5 nm, a technology which is already used by Apple in its latest M1 Pro and M1 Max chips and in the A15 SoC for iPhone 13. No doubt that the firm at the apple will take advantage of 3 nm engraving for its next generation of in-house chips …

Because it must be understood that the race for fine engraving is not only an industrial feat. It has very significant real consequences on the circuits and the devices which use them. The principle is simple: the finer the engraving, the more elements (transistors) can be integrated into an electronic circuit, the more said circuit integrates calculation and cache memory units, and therefore the more efficient it is. Better still, the finer the engraving, the shorter the internal links, the less energy losses there are, the lower the power consumption, and therefore the more economical the circuit, which has a direct impact on the autonomy in mobile devices (phones, tablets, laptops, etc.). This is why all chip designers and manufacturers are constantly seeking to improve the etching process, aiming for extreme finesse, and always pushing the limits of applied physics, which is today at the nanometric scale.

Collaboration with Intel for 2nm technology in 2024

If the announcement of the upcoming switch to 3 nm at TMSC is also important, it is first of all because it proves that the founder has succeeded in removing the many technical obstacles linked to this development by optimizing in particular its lithography process, which constitutes a great technological advance – and, secondly, because it paves the way for a new generation of chips, both more powerful and more economical. Especially since this advance will not benefit only Apple, even if the firm of Tim Cook will undoubtedly be the first served. And if AMD will make a smooth transition to 5 nm with its Zen 4 architecture, which will arrive in early 2022, it is easy to imagine future Ryzen and Epyc processors benefiting from 3 nm engraving. Ditto for Qualcomm, Nvidia and the others. “Others” among which are now Intel.

Indeed, according to Digitimes Asia, representatives of Intel should visit TSMC in December to finalize orders for components engraved in 3 nm. Aware of its technological and industrial backwardness, the American giant is counting on the capabilities of the Taiwanese founder to manufacture some of its future processors, in addition to its own factories. Intel would like to make sure now that Apple will not absorb all of the initial production, when negotiations should start for a collaboration on 2 nm engraving already scheduled for 2024.