You will also be interested

[EN VIDÉO] Live and work like on the Moon or on Mars The Hawai’i Space Exploration Analog and Simulation (HI-SEAS) is a research station installed at an altitude of some 2,500 meters, in a dome of approximately 110 square meters, on the flanks of the Mauna Loa volcano, in Hawaii. The objective: to simulate the life of human colonists who will go to settle on the Moon or on Mars. Not only to understand how astronauts will be able to interact with each other in difficult conditions, but also to develop the most suitable methods and equipment for living and researching on the Moon and Mars. © HI-SEAS

Thales Alenia Space has won a contract from the European Space Agency (ESA) to make a demonstrator lunar allowing to extractoxygen on the Moon. As Roger Ward, Technical Director of Thales Alenia Space in England, explains for ” to be able to reside permanently on the Moon, the astronauts will have to exploit the resources they find in situ rather than transporting them from Earth “. This is particularly the case of oxygen, which will be useful for human respiration and the production ofpropellants. Indeed, it is difficult to see Man transporting from Earth all his essential needs on the moonespecially if he counts to reside for very long periods.

The Complex Challenge of Creating Oxygen on the Moon to Support Human Life

This demonstrator must validate the ability to use resources in situ (ISRU- In Situ Resource Use), in this case the production of oxygen, in the quantities required by future lunar colonies. For this he will use molten salt and theelectrolysis to extract oxygen from moon rock, or ” regolith “.

In detail, the European Space Agency wants this demonstrator to extract 50 to 100 grams of oxygen from lunar regolith with a capacity to extract 70% of the oxygen present in a sample. Another constraint, the demonstration must be carried out within 10 days. This constraint is explained by ESA’s desire to limit the costs of the demonstrator that will work with theenergy solar, during a single lunar day which, let us remember, lasts 15 days. The mission will turn off and end at nightfall, due to lack of energy.

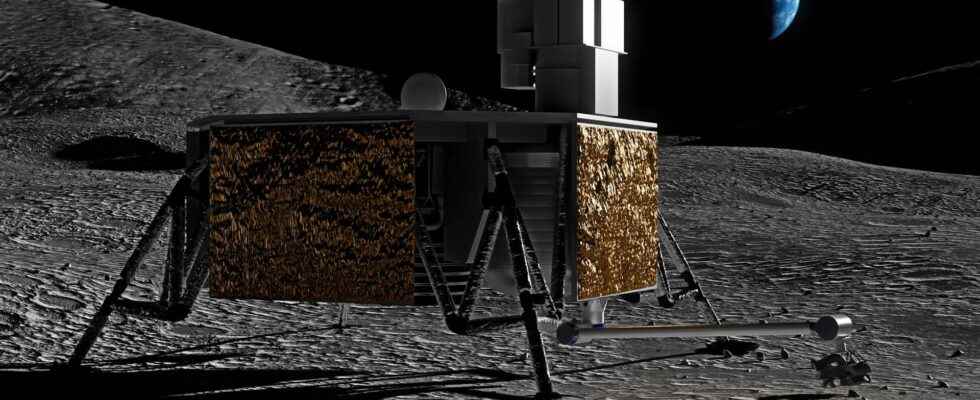

This demonstrator will be designed to fly on a range of potential lunar landers, including of course the multirole lander European Large Logistic Lander (E3L) from ESA.

The floor is given to Roger Ward, technical director of Thales Alenia Space in England.

Futura: Does Thales Alenia Space already have an idea of the extraction technique it wants to test and use on the Moon?

Roger Ward: The Thales Alenia Space team uses the Metalysis FFC process, developed in the United Kingdom, to extract oxygen by electrolysis and molten salt.

Futura: It seems that the use of electrolysis is not optimal. What do you think ?

Roger Ward: The optimization of any process operating on the Moon must take into account many different aspects, beyond the performance of the process on Earth. The project continually evaluates the design to determine the amount of oxygen produced relative to the mass and to power. We are well aware that any process operating on the Moon must be more cost effective than supplying oxygen from Earth.

Futura: Your demonstrator should extract 50 to 100 grams of oxygen to validate the concept as well as the technological choices?

Roger Ward: Beyond the “quantity of oxygen produced” aspect, our demonstrator aims to fully characterize the operation of the process on the Moon.

Futura: But what performance are you aiming for for an operational unit? From 300 to 400 liters of oxygen for one kilogram of regolith?

Roger Ward: The payload concept is modular, scalable and primarily designed to demonstrate that the technologies work and to optimize the processes and materials used. Some of these processes and materials are new to the project and therefore performance of a business unit cannot be disclosed at this time.

Futura: What are the constraints imposed by the European Space Agency?

Roger Ward: The focus is on demonstrating the process and technology that would make oxygen generated on the Moon cheaper than oxygen transported from Earth.

Futura: What are the main difficulties in designing such equipment? Is gravity a major issue?

Roger Ward: The gravity is not the main challenge. The main challenges are lunar soil, or regolith, and molten salt. Lunar regolith is unlike anything found on Earth, as it is produced in a vacuum by the bombardment of heavy particles by the solar wind and the collision of meteorites. In the absence of humidity andatmosphere, the particles are very small, sometimes statically charged and jagged, which makes the regolith very sticky and very difficult to handle and process. The molten salt will be at a high temperature, which is not too much of a problem on Earth, but on the surface of the Moon, the use of light aerospace materials and vacuum is very difficult. Therefore, to address these two technological challenges (and many others), a program of technological tests will be carried out on Earth in order to ensure that the equipment and the process operate in as representative an environment as possible before the construction final for launch.

Support your independent scientific media: discover our subscription formulas!

4 good reasons to subscribe to Futura on Patreon:

- A site without any advertising from 3.29 euro per month.

- It is without commitment.

- Access to priority content, in preview, just for you.

- You support our business in the best possible way. A real motivation for us!

Interested in what you just read?