In the United States, a 20-year-old woman suffering from a malformation in theear received a transplant designed from human cells and a 3D printer. This world first helps people with microtia, a anomaly congenital external ear. In the future, this technology may extend to other therapeutic areas.

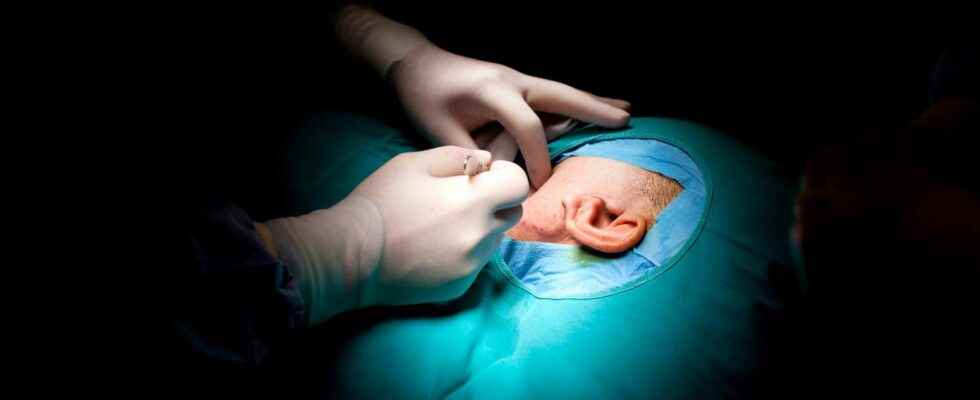

On June 2, the team of Arturo Bonilla, founder and director of Microtia-Congenital Ear Deformity Institute in the United States, performed a transplant ofimplant of one human ear created from a 3D printer. Called AuriNovo, this implant was developed by 3DBio Therapeutics, a biotechnology specialized in regenerative medicine.

This implant was designed to offer an alternative to people suffering from microtia, “a rare congenital malformation where one or both outer ears are absent or underdeveloped”, specifies the company in a press release. In Europe, this anomaly would affect 15 births out of approximately 100,000.

To create the prosthesis received by the 20-year-old patient, the specialists took cartilage cells from the patient before culturing them in the laboratory and mixing them withhydro gel of collagen. Then they have 3d printed the result in the shape of the “healthy” ear.

The implant is made of the patient’s cartilage cells

This operation could become a less invasive alternative to the surgery usually offered to people with microtia. ” I hope that AuriNovo will one day become the standard of care replacing the current surgical methods of ear reconstruction requiring the removal of cartilage costal or the use of implants in polyethylene porous (PPE) “, explains Arturo Bonilla.

With this technological advancethe ear should follow the growth and evolution of the transplanted person, as the founder of the Microtia-Congenital Ear Deformity Institute. ” We also expect this will result in a more flexible ear than reconstruction with an EPI implant. “.

This operation was carried out as part of a clinical test which takes place over five years in two US states, California and Texas. In total, eleven people, aged 6 to 25, with microtia, will receive an implant.

This clinical trial could also make it possible to extend this new technology to other therapeutic areas. ” Our initial indications focus on cartilage in the areas of reconstruction andorthopedicsincluding the treatment of complex nasal malformations and spinal degeneration “, explains Daniel Cohen, founder and CEO of 3DBio Thrapeutics.

A biocompatible human ear created by 3D printing

Thanks to a mold made by 3d printing and one freeze Composed of collagen and living cells, scientists have succeeded in creating an artificial, functional and biocompatible human ear that could be used for people suffering from deformities. Within months, the cells replace the collagen with real cartilage.

Article by Janlou Chaput, published on February 25, 2013

The surgery restorative could enter a new era: that of the3d printing. Usually, specialists use products that are similar in texture of the injured organ, or recover tissue from other parts of the body. This is typically what is done for ears.

Patients who have lost their outer ear as a result of a accidentof a cancer or a birth defect called microtia, receive either a prosthesis made of a material resembling the touch of mousse of polystyreneor have part of the cartilage of their ribs which the surgeon uses to shape the pavilion. Often this last strategy, in addition to being painful, turns out to be without real success.

But these times could be over in a few years thanks to researchers from thecornell university (New York). In the open access journal Plos Onethey explain how they managed to make a biocompatible artificial ear with modern tools.

A 3D printer, some gel, and you get an ear

The first step is to build a three-dimensional image of the ear to be shaped. Thanks to a 3D printer, the photo becomes a hollow mold with the shape of the pavilion and the lobe. A gel is injected into it, made up of collagen mixed with ear cells from cow. After solidificationthe prosthesis is placed in the nutrient culture medium in order to feed the cells so that they can form cartilage. After a few days, the ear is ready to be put in place.

To verify the biocompatibility and the viability of their structure, the authors implanted the artificial ears on the back of rats. The graft took well and after three months, the prosthesis had become cartilaginous, like the natural organ. Proof that the device can persist in a living organism.

Artificial ears available in a few years

From design to installation, such a process only takes a few days to implement. The authors estimate at half a day the time required to obtain the Photo of the ear. 3D printing takes approximately 24 hours. The injection of the gel requires 30 minutes and its solidification only 15 minutes. Add to that the few days of cultivation and you’re done.

Scientists now hope to be able to work with human ear cells, and especially cells from a patient, to be able to limit the risks of transplant rejection inherent in any implantation with living tissue.

For patients with microtia, the researchers point out that the best age to perform reconstructive surgery is around 5 or 6 years old. At this age, the ear is normally 80% of its adult size. The first human trials are expected in three years. If the test requests are heard…

Special offer: for Father’s Day, offer the best of Science!

Your father is a great science enthusiast and unusual discoveries? And if you offer him a superb scientific exploration in paper format? Benefit from -20% on the Mag Futura (special offer: €15 instead of 19 €): 220 pages to explore 4 scientific issues that will shape our future!

Mag Futura is:

- 4 major scientific questions for 2022, from the Earth to the Moon

- 220 pages, 60 experts: no fake news, just science

- Home delivery with electronic gift card

- An independent scientific media

Interested in what you just read?